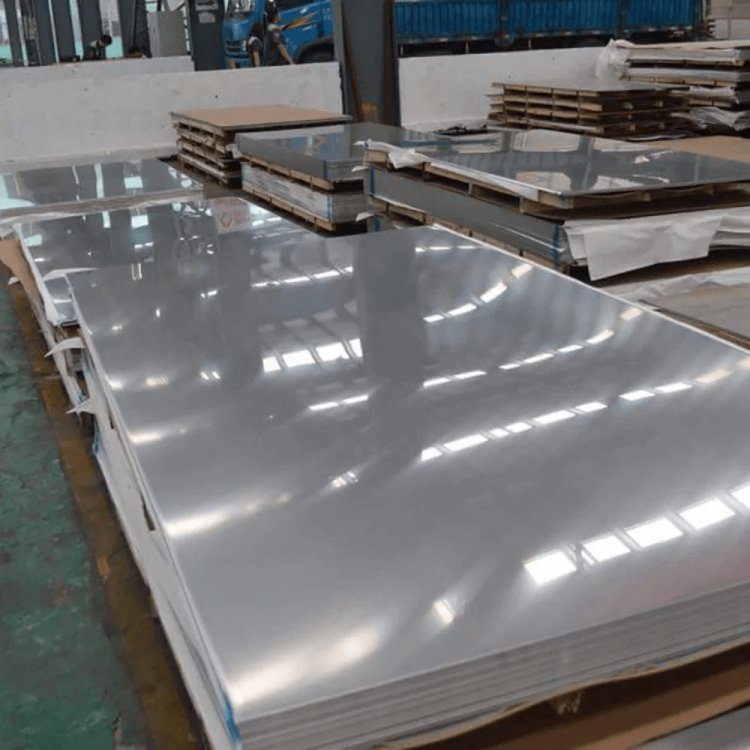

Advantages of Using Stainless Steel 316L Plates in Marine Environments

Explore the unparalleled benefits of utilizing stainless steel 316L plates in marine environments. Discover how this corrosion-resistant alloy withstands harsh conditions, maintains structural integrity, and contributes to the longevity of marine equipment and structures.

Introduction:

In the world of marine engineering and construction, durability, corrosion resistance, and strength are paramount. Among the plethora of materials available, stainless steel 316L plates stand out as a preferred choice for various marine applications. From shipbuilding to offshore structures, these plates offer a myriad of advantages that ensure longevity and reliability in harsh marine environments.

Understanding Stainless Steel 316L Plates

Stainless steel 316L is a low-carbon variation of the renowned 316-grade stainless steel. It's known for its exceptional corrosion resistance, especially in chloride environments, making it ideal for marine applications. The addition of molybdenum further enhances its corrosion resistance, particularly against pitting and crevice corrosion, which are common in seawater.

Advantages in Marine Environments

Superior Corrosion Resistance

One of the primary advantages of using stainless steel 316L plates in marine environments is their unparalleled corrosion resistance. Whether exposed to saltwater, brine solutions, or atmospheric conditions, these plates exhibit remarkable corrosion resistance, ensuring the longevity and structural integrity of marine vessels and structures.

Strength and Durability

Stainless steel 316L plates boast excellent mechanical properties, including high tensile strength and toughness. This inherent strength makes them capable of withstanding the harsh conditions prevalent in marine environments, such as heavy loads, extreme temperatures, and dynamic forces encountered during operation.

Low Maintenance Requirements

In maritime applications, minimizing maintenance is crucial for operational efficiency and cost-effectiveness. Stainless steel 316L plates require minimal maintenance due to their corrosion-resistant properties, reducing the need for frequent inspections, repairs, and replacements. This translates to significant savings in both time and resources over the lifespan of marine structures.

Aesthetic Appeal

Beyond their functional advantages, stainless steel 316L plates offer aesthetic appeal, contributing to the visual appeal of marine vessels and structures. Their sleek, polished finish adds a touch of sophistication, making them an attractive choice for architectural elements, handrails, and other visible components in marine environments.

Environmental Sustainability

As environmental concerns become increasingly significant, the sustainability of materials used in marine construction comes into focus. Stainless steel is inherently sustainable, as it is 100% recyclable without any loss of quality. Additionally, its durability and longevity contribute to reduced material consumption and waste generation over time, making it an environmentally responsible choice for marine applications.

Conclusion

In the challenging and corrosive environment of the sea, the choice of materials plays a pivotal role in ensuring the longevity, safety, and performance of marine structures and vessels. Stainless steel 316L plates emerge as a top contender, offering a winning combination of superior corrosion resistance, strength, durability, low maintenance requirements, aesthetic appeal, and environmental sustainability. By leveraging the advantages of stainless steel 316L, marine engineers and designers can navigate the seas with confidence, knowing that their creations are built to withstand the rigors of the marine environment for years to come.

What's Your Reaction?

![Blog Submission Sites 2024 [High DA]](https://blognow.co.in/uploads/images/202306/image_100x75_6494a03eaff5e.jpg)

![Article Submission Sites 2023 [High DA & PA]](https://blognow.co.in/uploads/images/202307/image_100x75_64c4181f17036.jpg)

![Classified Submission Sites 2023 [High DA & PR]](https://blognow.co.in/uploads/images/202306/image_100x75_649dcd5260808.jpg)

![Article Submission Sites 2023 [High DA & PA]](https://blognow.co.in/uploads/images/202307/image_750x415_64c4181f08ed5.jpg)

![Classified Submission Sites 2023 [High DA & PR]](https://blognow.co.in/uploads/images/202306/image_750x415_649dcd5247eeb.jpg)

![Blog Submission Sites 2024 [High DA]](https://blognow.co.in/uploads/images/202306/image_750x415_6494a03e96bfa.jpg)