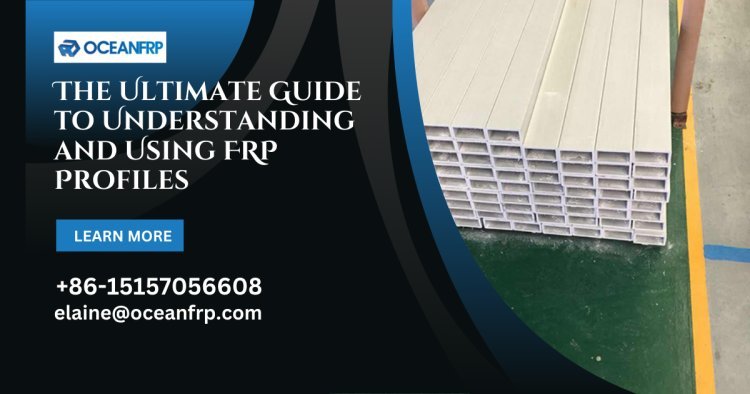

The Ultimate Guide to Understanding and Using FRP Profiles

In the realm of modern construction, architecture, and industrial applications, the demand for lightweight, durable, and versatile materials is ever-growing. Fiber Reinforced Plastic (FRP) profiles have emerged as a popular choice for fulfilling these requirements. With their exceptional strength, corrosion resistance, and customizable properties, FRP profiles offer a wide range of applications across various industries. In this comprehensive guide, we will delve into the fundamentals of FRP profiles, exploring their composition, manufacturing process, key characteristics, and practical uses. Whether you're an engineer, architect, or project manager, understanding FRP profiles can unlock a world of possibilities for your projects. Join us as we embark on the journey to unravel the mysteries of FRP profiles, brought to you by Quzhou Ocean New Material Co., Ltd., a leading manufacturer in the field.

Understanding FRP Profiles

What Are FRP Profiles?

FRP profiles, also known as fiberglass profiles or fiberglass reinforced plastic profiles, are structural components made from a composite material comprising fiberglass reinforcements and a polymer resin matrix. These profiles are manufactured through a process called pultrusion, which involves pulling fibers through a resin bath, then through a heated die to shape and cure the composite into the desired profile shape.

Composition of FRP Profiles

FRP profiles consist of several layers, each serving a specific purpose:

- Fiberglass Reinforcements: The primary strength component of FRP profiles, fiberglass reinforcements are typically composed of continuous glass fibers, such as E-glass or S-glass. These fibers provide tensile strength and stiffness to the composite material.

- Resin Matrix: The resin matrix binds the fiberglass reinforcements together, providing cohesion and protecting the fibers from environmental degradation. Common resin matrices used in FRP profiles include polyester, vinyl ester, and epoxy resins.

- Additives: Various additives may be incorporated into the resin matrix to enhance specific properties of the FRP profiles, such as UV resistance, fire retardancy, or color pigmentation.

Key Characteristics of FRP Profiles

High Strength-to-Weight Ratio

One of the most significant advantages of FRP profiles is their impressive strength-to-weight ratio. Despite being lightweight, FRP profiles offer excellent strength and stiffness, making them suitable for structural applications where weight reduction is critical.

Corrosion Resistance

FRP profiles exhibit exceptional resistance to corrosion, making them ideal for use in harsh environments where traditional materials like steel or wood would corrode or degrade. This corrosion resistance ensures the longevity and durability of FRP profiles in applications exposed to moisture, chemicals, or corrosive gases.

Design Flexibility

FRP profiles offer unparalleled design flexibility, allowing for the creation of complex shapes and geometries to meet specific project requirements. With customizable properties such as color, texture, and surface finish, FRP profiles can be tailored to suit a wide range of aesthetic and functional needs.

Thermal and Electrical Insulation

Due to their non-conductive nature, FRP profiles provide excellent thermal and electrical insulation. This property makes them suitable for applications where electrical conductivity or thermal bridging must be avoided, such as in electrical enclosures or building façades.

Practical Uses of FRP Profiles

Construction and Architecture

In the construction and architecture industries, FRP profiles find numerous applications, including:

- Structural Supports: FRP profiles are used as structural beams, columns, and trusses in building construction, offering lightweight alternatives to traditional materials like steel or concrete.

- Cladding and Facades: FRP profiles can be used as cladding panels or facade elements, providing weather-resistant and aesthetically pleasing finishes to buildings.

- Roofing and Decking: FRP profiles are utilized as roofing panels, skylights, and decking materials, offering durable and lightweight solutions for outdoor structures.

Infrastructure and Transportation

In infrastructure and transportation projects, FRP profiles are employed in various applications, such as:

- Bridge Decking: FRP profiles are used as lightweight decking materials for pedestrian bridges and walkways, providing corrosion-resistant alternatives to traditional materials like wood or steel.

- Railings and Guardrails: FRP profiles serve as durable and low-maintenance railing systems for highways, railways, and public spaces, offering high strength and corrosion resistance.

Industrial and Marine Applications

In industrial and marine environments, FRP profiles are utilized for:

- Equipment Enclosures: FRP profiles are used to fabricate enclosures and housings for industrial equipment, providing protection against corrosion, chemicals, and harsh weather conditions.

- Marine Structures: FRP profiles are employed in the construction of docks, marinas, and offshore platforms, offering corrosion-resistant and durable solutions for marine environments.

Manufacturing Process of FRP Profiles

Pultrusion Process

The pultrusion process is the primary method used to manufacture FRP profiles. It involves the following steps:

- Fiber Impregnation: Continuous strands of fiberglass reinforcements are pulled through a resin bath, saturating them with the desired resin matrix.

- Molding and Shaping: The resin-impregnated fibers pass through a heated die, where they are molded into the desired profile shape and cured.

- Cooling and Cutting: Once cured, the profiles are cooled and cut to the desired lengths, ready for further processing or installation.

Advantages of FRP Profiles Over Traditional Materials

Lightweight Design

FRP profiles offer significant weight savings compared to traditional materials like steel or concrete, reducing transportation costs and simplifying installation.

Corrosion Resistance

Unlike metals, which can corrode and degrade over time, FRP profiles exhibit exceptional resistance to corrosion, ensuring long-term durability and reliability in harsh environments.

Design Flexibility

FRP profiles offer unparalleled design flexibility, allowing for the creation of complex shapes and geometries to meet specific project requirements.

Low Maintenance Requirements

Due to their inherent resistance to corrosion and weathering, FRP profiles require minimal maintenance over their lifespan, reducing lifecycle costs and downtime.

In conclusion, FRP profiles offer a myriad of benefits, including high strength, corrosion resistance, design flexibility, and low maintenance requirements. With their diverse range of applications across industries such as construction, infrastructure, transportation, and marine, FRP profiles are revolutionizing the way we build and design structures. As a leading manufacturer in the field, Quzhou Ocean New Material Co., Ltd. provides high-quality FRP profiles tailored to meet the unique needs of various projects. Whether you're constructing a building, a bridge, or an industrial facility, FRP profiles offer the durability, reliability, and versatility required to bring your vision to life.

FAQs

What are FRP profiles?

FRP profiles, or fiberglass reinforced plastic profiles, are structural components made from a composite material comprising fiberglass reinforcements and a polymer resin matrix.

What are the key characteristics of FRP profiles?

FRP profiles exhibit high strength-to-weight ratio, corrosion resistance, design flexibility, and thermal and electrical insulation properties.

What are the practical uses of FRP profiles?

FRP profiles are used in construction, architecture, infrastructure, transportation and marine applications for structural supports, cladding, roofing, decking, bridge decking, railings, guardrails, equipment enclosures, and marine structures.

How are FRP profiles manufactured?

FRP profiles are manufactured through the pultrusion process, which involves fiber impregnation, molding, shaping, curing, cooling, and cutting.

What are the advantages of FRP profiles over traditional materials?

FRP profiles offer advantages such as lightweight design, corrosion resistance, design flexibility, and low maintenance requirements compared to traditional materials like steel or concrete.

How can I incorporate FRP profiles into my projects?

To incorporate FRP profiles into your projects, consult with Quzhou Ocean New Material Co., Ltd. Their team of experts can provide guidance on product selection, customization, installation, and maintenance, ensuring the success of your projects.

Where can I find more information about FRP profiles?

For more information about FRP profiles, visit Quzhou Ocean's website or contact their sales team directly. They can provide detailed product information, specifications, case studies, and assistance with your specific project requirements.

What's Your Reaction?

![Blog Submission Sites 2024 [High DA]](https://blognow.co.in/uploads/images/202306/image_100x75_6494a03eaff5e.jpg)

![Article Submission Sites 2023 [High DA & PA]](https://blognow.co.in/uploads/images/202307/image_100x75_64c4181f17036.jpg)

![Classified Submission Sites 2023 [High DA & PR]](https://blognow.co.in/uploads/images/202306/image_100x75_649dcd5260808.jpg)

![Article Submission Sites 2023 [High DA & PA]](https://blognow.co.in/uploads/images/202307/image_750x415_64c4181f08ed5.jpg)

![Classified Submission Sites 2023 [High DA & PR]](https://blognow.co.in/uploads/images/202306/image_750x415_649dcd5247eeb.jpg)

![Blog Submission Sites 2024 [High DA]](https://blognow.co.in/uploads/images/202306/image_750x415_6494a03e96bfa.jpg)