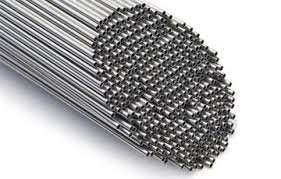

Understanding the SS Capillary Tube: A Comprehensive Guide

The SS capillary tube is a critical component in various industrial applications, revered for its precision, durability, and versatility. This article delves into the intricate details of SS capillary tubes, exploring their properties, applications, manufacturing process, and benefits. Whether you're in the medical, engineering, or manufacturing sector, understanding the nuances of SS capillary tubes can significantly enhance your operational efficiency and product quality.

What is an SS Capillary Tube?

An Stainless Steel Capillary Tube is a small-diameter tube made from stainless steel. These tubes are known for their precise internal diameter, making them ideal for applications requiring high accuracy in fluid or gas flow. The 'SS' in the name stands for stainless steel, a material renowned for its corrosion resistance, strength, and longevity.

Key Properties of SS Capillary Tubes

High Corrosion Resistance

Stainless steel capillary tubes are highly resistant to corrosion, making them suitable for harsh environments, including those involving chemicals and seawater.

Precision and Accuracy

The manufacturing process of SS capillary tubes ensures a high degree of precision in both internal and external diameters. This precision is crucial in applications where even the smallest deviation can lead to significant performance issues.

Mechanical Strength

SS capillary tubes exhibit excellent mechanical strength, enabling them to withstand high pressures without deforming or bursting.

Temperature Resistance

These tubes can operate effectively in extreme temperatures, both hot and cold, making them versatile for a wide range of applications.

Applications of SS Capillary Tubes

Medical Devices

In the medical field, SS capillary tubes and Stainless Steel Corrugated Tube are used in hypodermic needles, catheters, and surgical instruments due to their biocompatibility and precision.

Chromatography

SS capillary tubes are integral in gas and liquid chromatography systems, where they help in the accurate separation of chemical compounds.

Instrumentation and Control Systems

These tubes are employed in various instrumentation and control systems, including pressure gauges and flow meters, where precision is paramount.

Aerospace and Defense

In aerospace and defense, SS capillary tubes are used in hydraulic and fuel systems, benefiting from their ability to handle high pressures and resist corrosion.

Automotive Industry

The automotive industry uses these tubes in fuel injection systems and brake lines, where reliability and durability are critical.

Manufacturing Process of SS Capillary Tubes

Material Selection

The process begins with the selection of high-quality stainless steel, typically grades like 304, 316, or 321, known for their superior properties.

Tube Drawing

The stainless steel is drawn through a die to create a tube with the desired outer diameter. This process involves multiple stages of drawing and annealing to ensure precision and consistency.

Annealing

Annealing is a heat treatment process that softens the metal, improving its ductility and reducing hardness, which is essential for further processing.

Cold Drawing

Cold drawing involves pulling the tube through a die at room temperature, refining the tube’s diameter and improving its surface finish.

Cleaning and Inspection

The tubes undergo rigorous cleaning to remove any residues or impurities. Inspection follows, using techniques like ultrasonic testing and eddy current testing to ensure the tubes meet strict quality standards.

Cutting and Finishing

Finally, the tubes are cut to the desired lengths and finished to meet specific application requirements. This step may also involve polishing to enhance the surface quality.

Advantages of Using SS Capillary Tubes

Longevity and Durability

Due to their resistance to corrosion and wear, SS capillary tubes have a long service life, reducing the need for frequent replacements.

High Precision

The precise internal diameter of SS capillary tubes ensures accurate fluid and gas flow, which is critical in applications like medical devices and analytical instruments.

Versatility

SS capillary tubes can be used in a wide range of applications, from medical to industrial, due to their adaptability to different environments and requirements.

Safety

In high-pressure applications, the mechanical strength of SS capillary tubes provides a safety margin, preventing failures that could lead to hazardous situations.

Selecting the Right SS Capillary Tube

Consider the Application

The specific requirements of your application will dictate the type of SS capillary tube needed. Consider factors such as pressure, temperature, and the nature of the fluid or gas being transported.

Choose the Right Material Grade

Different grades of stainless steel offer varying levels of corrosion resistance, strength, and flexibility. Select a grade that aligns with your application needs.

Check for Quality Standards

Ensure that the SS capillary tubes meet industry standards and certifications, which guarantee their quality and performance.

Evaluate Supplier Reliability

Partner with reputable suppliers who have a track record of delivering high-quality SS capillary tubes and provide excellent customer service and technical support.

Maintenance and Handling Tips

Regular Inspection

Periodically inspect the SS capillary tubes for signs of wear, corrosion, or damage to prevent unexpected failures.

Proper Storage

Store the tubes in a clean, dry environment to prevent contamination and corrosion. Use protective coverings if necessary.

Careful Handling

Handle the tubes with care during installation and maintenance to avoid bending or damaging them, which could affect their performance.

Future Trends in SS Capillary Tubes

Advanced Coatings

Research is ongoing into advanced coatings that can further enhance the corrosion resistance and durability of SS capillary tubes, extending their lifespan in harsh environments.

Miniaturization

As technology advances, there is a growing demand for even smaller and more precise capillary tubes, particularly in medical and analytical applications.

Sustainable Manufacturing

Efforts are being made to develop more sustainable manufacturing processes for SS capillary tubes, reducing environmental impact and improving efficiency.

Conclusion

The SS capillary tube is an indispensable component in many high-precision applications. Its combination of durability, precision, and versatility makes it an excellent choice for industries ranging from medical to automotive. By understanding the properties, applications, and manufacturing processes of SS capillary tubes, businesses can make informed decisions that enhance their operational efficiency and product quality.

What's Your Reaction?

![Blog Submission Sites 2024 [High DA]](https://blognow.co.in/uploads/images/202306/image_100x75_6494a03eaff5e.jpg)

![Article Submission Sites 2023 [High DA & PA]](https://blognow.co.in/uploads/images/202307/image_100x75_64c4181f17036.jpg)

![Classified Submission Sites 2023 [High DA & PR]](https://blognow.co.in/uploads/images/202306/image_100x75_649dcd5260808.jpg)

![Article Submission Sites 2023 [High DA & PA]](https://blognow.co.in/uploads/images/202307/image_750x415_64c4181f08ed5.jpg)

![Classified Submission Sites 2023 [High DA & PR]](https://blognow.co.in/uploads/images/202306/image_750x415_649dcd5247eeb.jpg)

![Blog Submission Sites 2024 [High DA]](https://blognow.co.in/uploads/images/202306/image_750x415_6494a03e96bfa.jpg)