Unlocking the Art of Dieline Printing: Crafting Precision in Packaging

In this blog, we’ll embark on a journey into the realm of dieline printing, exploring

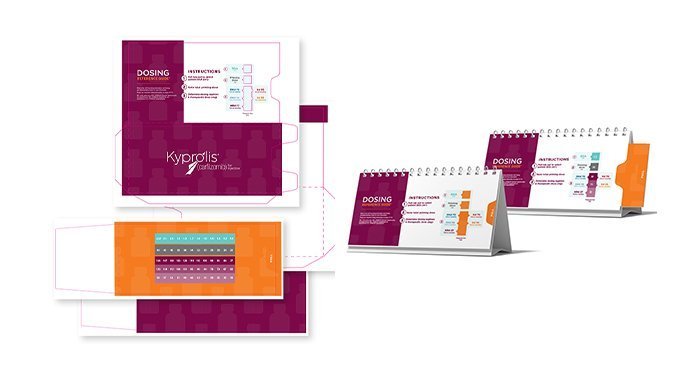

In the world of packaging, precision is paramount. Every fold, every cut, and every crease matters. This is where dieline printing comes into play, ensuring that packaging materials are crafted with meticulous accuracy. In this blog, we’ll embark on a journey into the realm of dieline printing, exploring what it is, its significance in various sectors such as food packaging dieline, packaging boxes, and tube packaging, and how it shapes the world of modern packaging.

The Essence of Dieline Printing

1. The Blueprint of Packaging

Dieline printing is, at its core, the blueprint for packaging. It’s the detailed outline that specifies the dimensions, cuts, and folds necessary to transform flat packaging material into a three-dimensional masterpiece.

2. Precision and Consistency

The precision and consistency of dieline printing are paramount. Any deviation can result in ill-fitting packaging, leading to product damage and a poor customer experience.

What Is a Dieline in Packaging?

1. The Backbone of Packaging Design

A dieline serves as the backbone of packaging design. It outlines the exact shape and size of each component, from the main box to inserts and sleeves, ensuring that they all fit together seamlessly.

2. Visual Representation

Dielines are visual representations of how a flat piece of material should be cut and folded to create the final packaging. They are essential guides for both designers and manufacturers.

Food Packaging Dieline: Ensuring Freshness and Safety

1. Customization for Food Products

Food packaging dielines are tailored to the specific needs of food products. They account for factors like food safety, preservation, and presentation.

2. Importance of Hygiene

Dieline printing for food packaging considers hygiene standards and regulations. It ensures that the packaging is safe for direct contact with food and prevents contamination.

Packaging Box Dieline: The Perfect Fit

1. Tailored to Product Dimensions

Packaging box dielines are customized to fit the dimensions of the product they encase. This ensures a snug fit, reducing the risk of damage during transit.

2. Branding and Aesthetics

Dielines for packaging boxes also take branding and aesthetics into account. They allow for the incorporation of logos, graphics, and other design elements.

Dieline for Packaging: From Concept to Creation

1. The Initial Design Phase

During the design phase, dieline templates are created to map out the packaging’s structure. This includes specifying where folds and cuts should occur.

2. Prototyping and Testing

Once the dieline is finalized, prototypes are created and tested. This step ensures that the packaging can be assembled correctly and that it provides the intended functionality.

Tube Packaging Dieline: Efficiency and Versatility

1. Ideal for Various Products

Dieline printing for half price packaging is versatile and suitable for various products, from cosmetics to pharmaceuticals. It offers an efficient way to create cylindrical packaging.

2. Space-Efficient and Cost-Effective

Tube packaging dielines are designed to minimize material waste, making them space-efficient and cost-effective. This is particularly important in mass production.

Dieline Printing Technology: Precision in Action

1. Cutting-Edge Technology

Dieline printing leverages cutting-edge technology, including CAD (Computer-Aided Design) software and precision cutting machines. These technologies ensure accuracy in dieline creation and execution.

2. Customization and Scalability

Modern dieline printing technology allows for easy customization and scalability. Whether you need a small batch or large-scale production, dieline printing can accommodate your needs.

The Future of Dieline Printing

1. Integration with Digital Design

Dieline printing is becoming more integrated with digital design tools, streamlining the design-to-production process and reducing errors.

2. Sustainable Practices

Sustainability is a growing concern in packaging. Future dieline printing practices will likely prioritize eco-friendly materials and efficient designs that reduce waste.

Conclusion: The Art of Precision in Packaging

Dieline printing is the unsung hero of the packaging world. It ensures that every package is a perfect fit, every fold is in its place, and every cut is precise. Whether it’s food packaging, packaging boxes, or tube packaging, dieline printing is at the heart of crafting packaging solutions that protect products and delight customers. As technology advances and sustainability becomes more crucial, dieline printing will continue to evolve, shaping the future of packaging with its precision and efficiency. In the intricate dance of packaging design and production, dieline printing orchestrates the symphony of perfection, ensuring that each package is a work of art in its own right.

What's Your Reaction?

![Blog Submission Sites 2024 [High DA]](https://blognow.co.in/uploads/images/202306/image_100x75_6494a03eaff5e.jpg)

![Article Submission Sites 2023 [High DA & PA]](https://blognow.co.in/uploads/images/202307/image_100x75_64c4181f17036.jpg)

![Classified Submission Sites 2023 [High DA & PR]](https://blognow.co.in/uploads/images/202306/image_100x75_649dcd5260808.jpg)

![Article Submission Sites 2023 [High DA & PA]](https://blognow.co.in/uploads/images/202307/image_750x415_64c4181f08ed5.jpg)

![Classified Submission Sites 2023 [High DA & PR]](https://blognow.co.in/uploads/images/202306/image_750x415_649dcd5247eeb.jpg)

![Blog Submission Sites 2024 [High DA]](https://blognow.co.in/uploads/images/202306/image_750x415_6494a03e96bfa.jpg)